Fibers are the basic component of all textiles, whether it's natural or synthetic. However, let's not mince words. There are differences between natural and synthetic fibers. Whether it's a matter of production, physical properties, or environmental impact, the two vary. Even between specific fabrics like comparing vinyl to cotton, the differences can be seen. There are also broader points that make them stand apart from each other.

Today, let's take a much deeper, more in-depth look at the key factors that separate natural fibers from synthetic ones. There are a few key elements that make them distinct from each other, whether they are strengths or weaknesses. It is more than just a matter of where they come from.

1Where They Come From

Advertisement

First, let's look at the obvious difference. Natural fibers are harvested from nature. Silk is made by silkworms, cotton grows on plants, wool is harvested from sheep, and so on. These come from natural processes, though the means of turning them into commercial textiles is certainly not.

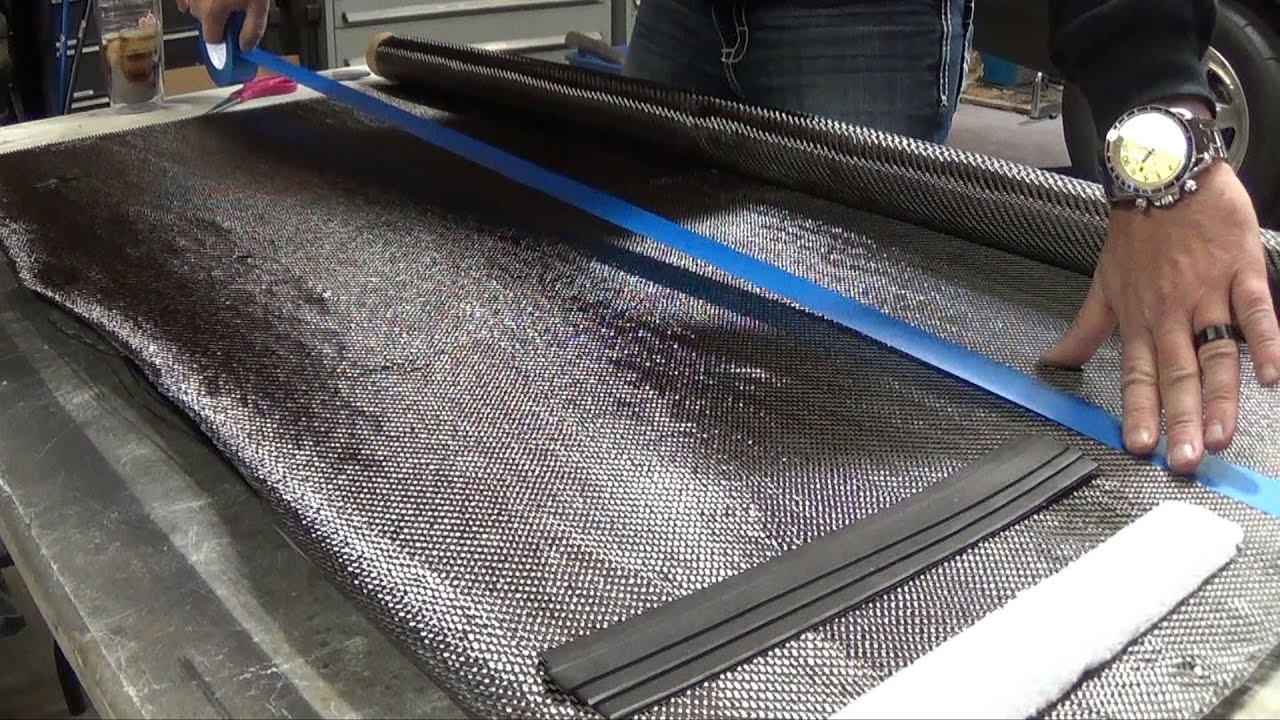

In contrast, synthetic fibers like polyester and rayon are made from oil-based products. Usually, they're plastics but some of them might be metallic in nature. This is the case for conductive fibers, the sort used in potential e-textiles and wearable technology.

Fiber Strength

Synthetic fibers are stronger and can take more punishment, even due to heavy wear and tear. This makes them ideal for any function that's likely to be exposed to the elements or extremes, such as tents, parachutes, and other outdoor applications.

However, their nature as oil-based is a double-edged sword. On one hand, it means water slides off them with ease and cleaning them to prevent stains from liquids is easy. However, they're not good for hot weather or intimate wear. In climates where heat and sweat are to be expected, synthetic fibers underperform and are uncomfortable.

.

Skin Comfort

Natural fibers are more comfortable on the skin. They are much softer and the texture plays well, adding to the general comfort. They're also much more breathable and absorbent, so they're less problematic to wear in intimate areas or in hotter climates. However, the production cost for making them is considerably higher than equivalent amounts of synthetic fabric.

Durability

Natural fibers are more likely to suffer through wear and tear. The production process doesn't compromise or push their natural state, so the fibers aren't "pressured." This means that their endurance is lower, along with their general tensile strength. With enough force, you can rip natural fiber textiles apart, but you'll need considerably more to do the same for a synthetic equivalent.

2Reactions to Temperature Extremes

Advertisement

Temperature extremes are a problem for synthetic fibers. They tend to become stiff when exposed to extreme cold, making cracking noises when you move. When exposed to extreme heat, they are unlikely to ignite but will melt instead. In contrast, natural fibers have a greater tolerance for the cold. Wool, in particular, is known for doing very well in the cold. Natural fabrics need to be directly lit to catch fire and are more flammable. Of them, silk burns most easily.

Care and maintenance of synthetic fibers are easy. Wash and let them dry. They won't distort or lose shape, nor will they stain easily. They're low-maintenance, making them attractive for people who don't have a lot of time to spend cleaning their wardrobe.

Natural fibers all have care instructions that must be followed. Failure to comply with the instructions will result in damage, possibly ruining them completely. Silk is best kept away from direct sunlight. Wool is prone to be attacked by moths, so should be treated to prevent this. Cotton and wool both might shrink in the wash if not cleaned as directed, with wool being more prone to this issue.

The discomfort of synthetic fibers can be problematic for upholstery and bedding, as well as clothing worn in intimate areas. Natural fabrics are much better at this. The exception is vinyl, which is functional for upholstery, particularly for vehicle interiors. The water resistance of synthetics also makes them the most viable choices for any upholstery used in maritime functions.

Natural fibers are less customizable than synthetic ones. While you can modify some properties with the right processing techniques, this doesn't change much. You're not going to make cotton as elastic as spandex, even if you put it through a Sintelli knitting machine. You can't make wool more lightweight by weaving it with a lighter fabric.

Synthetic fibers don't have this issue. Lab testing and development can be used to alter the properties of the fabrics before they go into mass production. Due to their plastic-based nature, some things can't be removed completely. However, their properties can be tweaked to provide additional elasticity, "weight," or other elements.

Conclusion

Natural fibers have many advantages over synthetic ones. However, the same could be said in reverse. The fact is that neither one is truly going to dominate the other, as there are limitations inherent to each that keep them from being truly universal. There are some applications where synthetic is better and others where natural is the way to go.